Crafting Efficiency : ERP in Modern Manufacturing

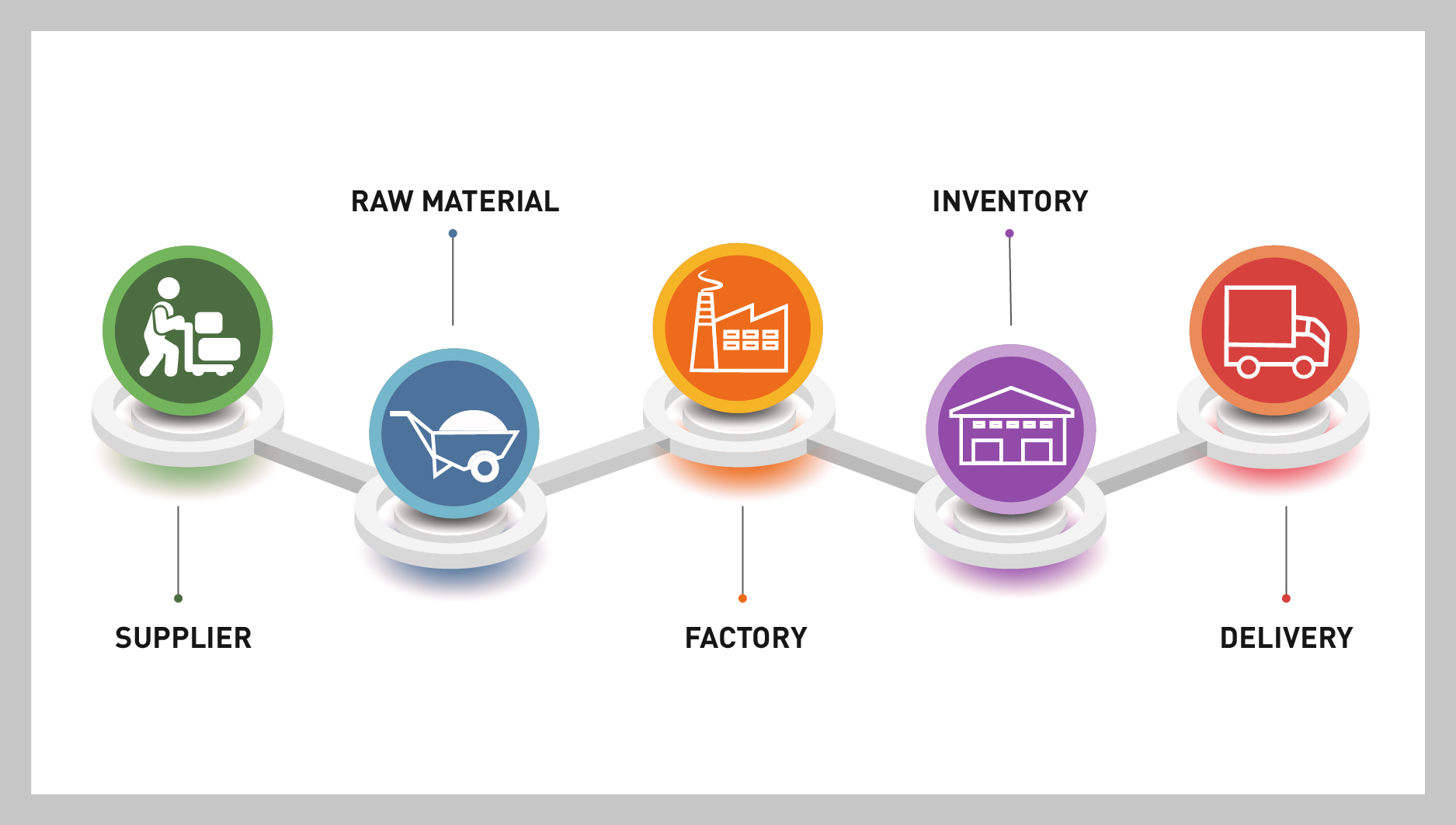

In the fast-paced world of manufacturing, efficiency is key to success. The manufacturing industry is fundamental for development, playing a pivotal role in transforming raw materials into finished products. This multifaceted sector encompasses a diverse range of activities. However, there are issues that each sector may face in today’s world without technology. With the evolving industry the challenges faced by businesses also evolve. In the absence of technology adoption, the manufacturing industry scuffles with inefficiencies across various fronts. Manual work results in increased labor costs, a higher likelihood of errors, and slower production cycles. Challenges in inventory management lead to inaccuracies and difficulties in maintaining optimal stock levels, impacting financial outcomes. In all these the quality control gets hampered. Companies these days are turning to advanced solutions like Enterprise Resource Planning (ERP) systems to overcome the obstacles posed by manual manufacturing processes.

With FACT ERP.NG the manufacturing industry can tackle and combat many issues.

Let’s see how FACT can help you optimize your business processes –

- Compliance and Quality Assurance Difficulty : Adherence to industry regulations and quality standards is challenging if done manually. Making sure that every step in the production process meets compliance requirements is a tedious task. With FACT’s Compliance Monitor Guru, managing compliances will become easier than ever! With the use of escalations and repeated alerts, compliances will never be missed

- Error-Prone Processes : Errors are inevitable in manual data entry and calculations. Miscalculations in bills of materials (BOM), inaccurate inventory records, and production scheduling errors can result in costly mistakes, affecting the bottom line. FACT ERP.NG ensures the accuracy of BOM by centralizing the management of materials and components. With unlimited levels of BOM, the system allows for meticulous detailing, reducing the risk of miscalculations and ensuring that each product is assembled with precision

- Restricted Control : In a manual system, tracking and controlling various stages of production become dismaying tasks. Lack of real-time visibility into inventory levels, work-in-progress (WIP), and production schedules can lead to delays and inefficiencies. With our Inventory Position and Inventory Position (WIP), you can keep track of the inventory position and supplies in realtime

To conclude, in a world where every minute counts, the manual handling of manufacturing procedures can no longer be counted on to keep up with the demands of the industry. FACT has emerged as a game-changer by addressing the challenges faced in manual manufacturing processes. It is about time for manufacturers to embrace the future of manufacturing with FACT ERP.NG, leaving behind the hindrances of manual processes.